Sheet Metal Work

The Timeless Relevance of Traditional Marking Out and Pattern Skills in Modern Engineering

In the golden era of engineering craftsmanship during the 1960s, 70s, and 80s, marking out and pattern-making were considered foundational skills. Long before the advent of 2D CAD systems and 3D modelling software, these manual techniques represented the heart of design and fabrication processes. Today, as the engineering world is increasingly dominated by advanced digital tools, the knowledge and insights gained from those traditional practices remain not only relevant but invaluable.

A Foundation in Understanding Material Behaviour

Marking out and pattern-making were rooted in a deep understanding of how metal behaves when cut, formed, and assembled. Engineers and fabricators of the time relied on hands-on experience and meticulous calculations to:

- Anticipate material stretch and shrink during forming.

- Optimise cutting layouts to minimise waste.

- Design patterns that could account for tolerances and assembly requirements.

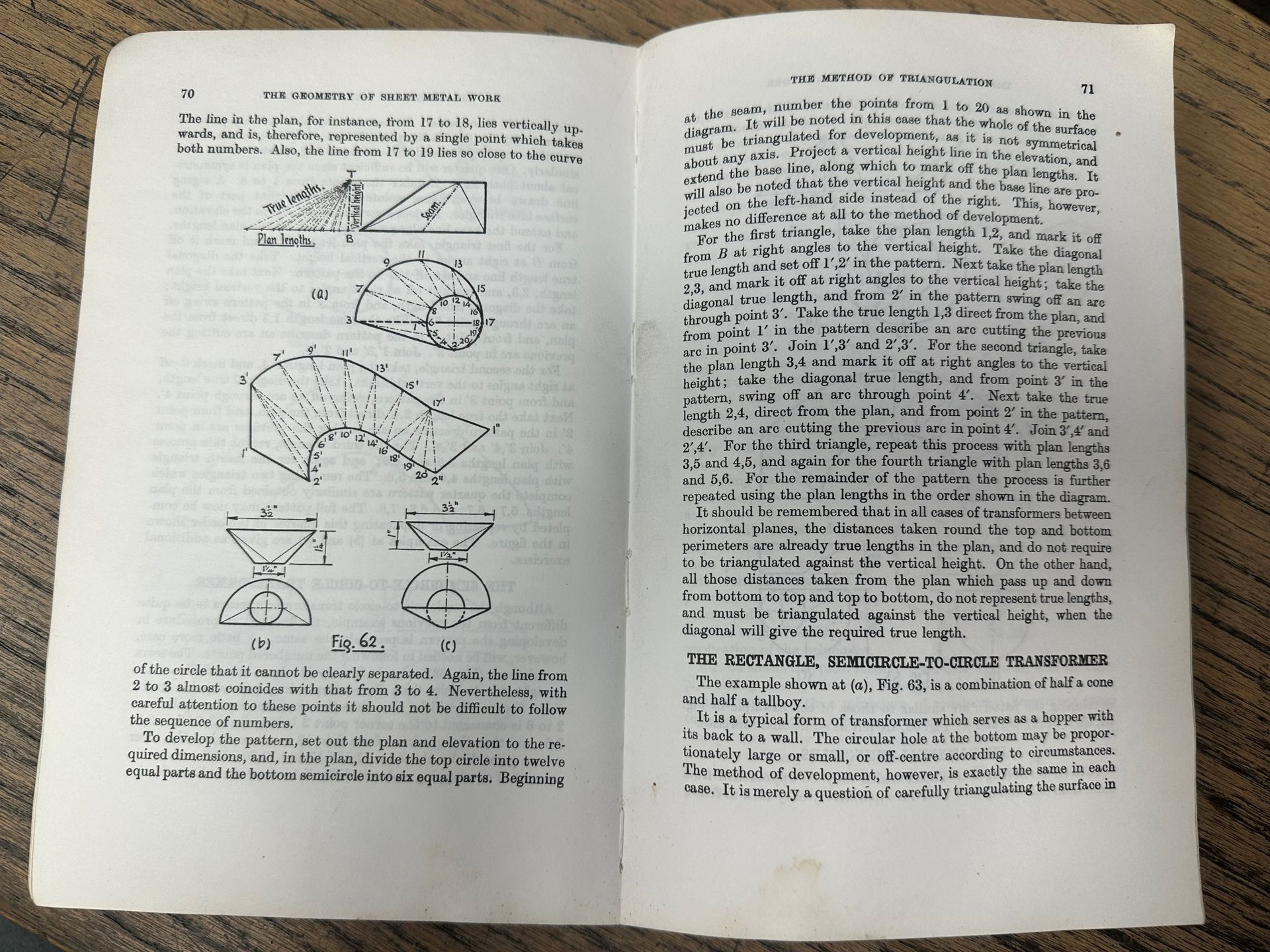

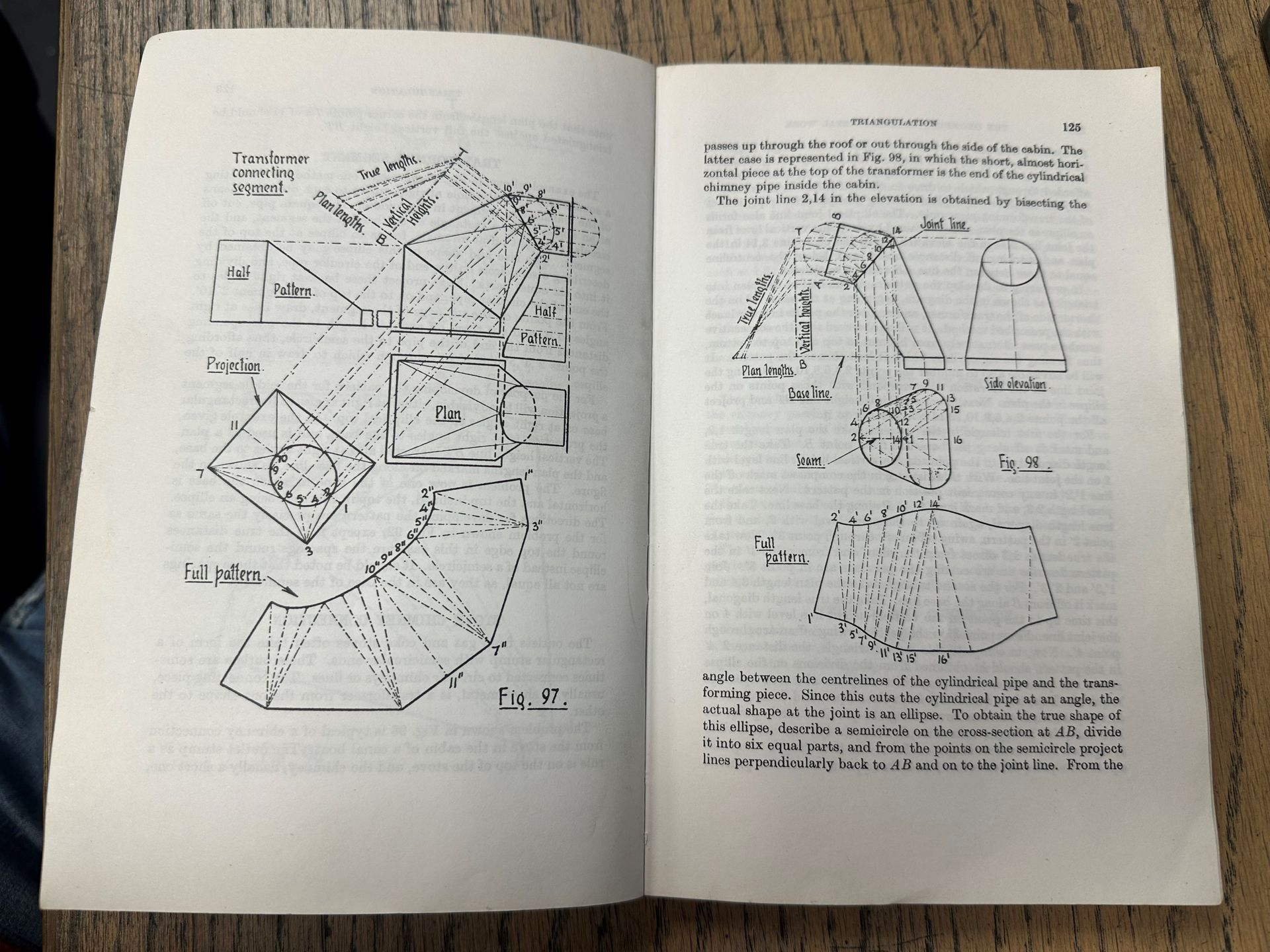

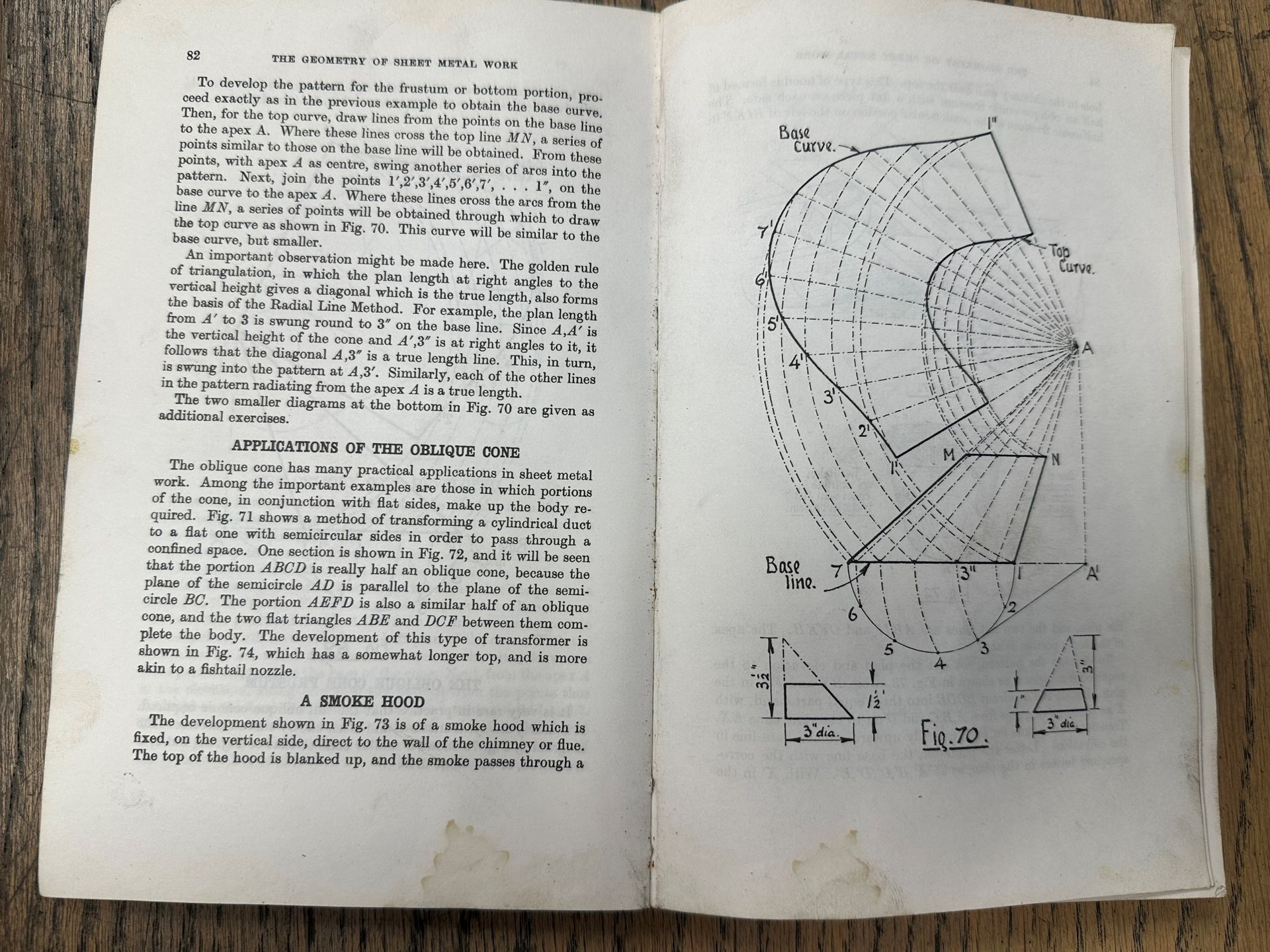

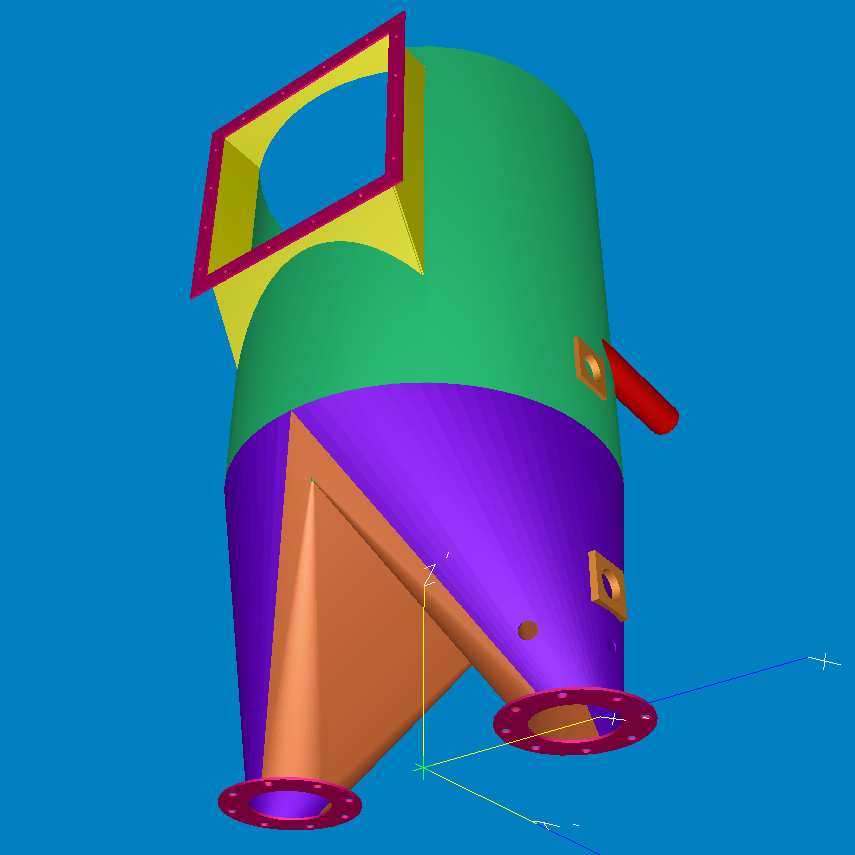

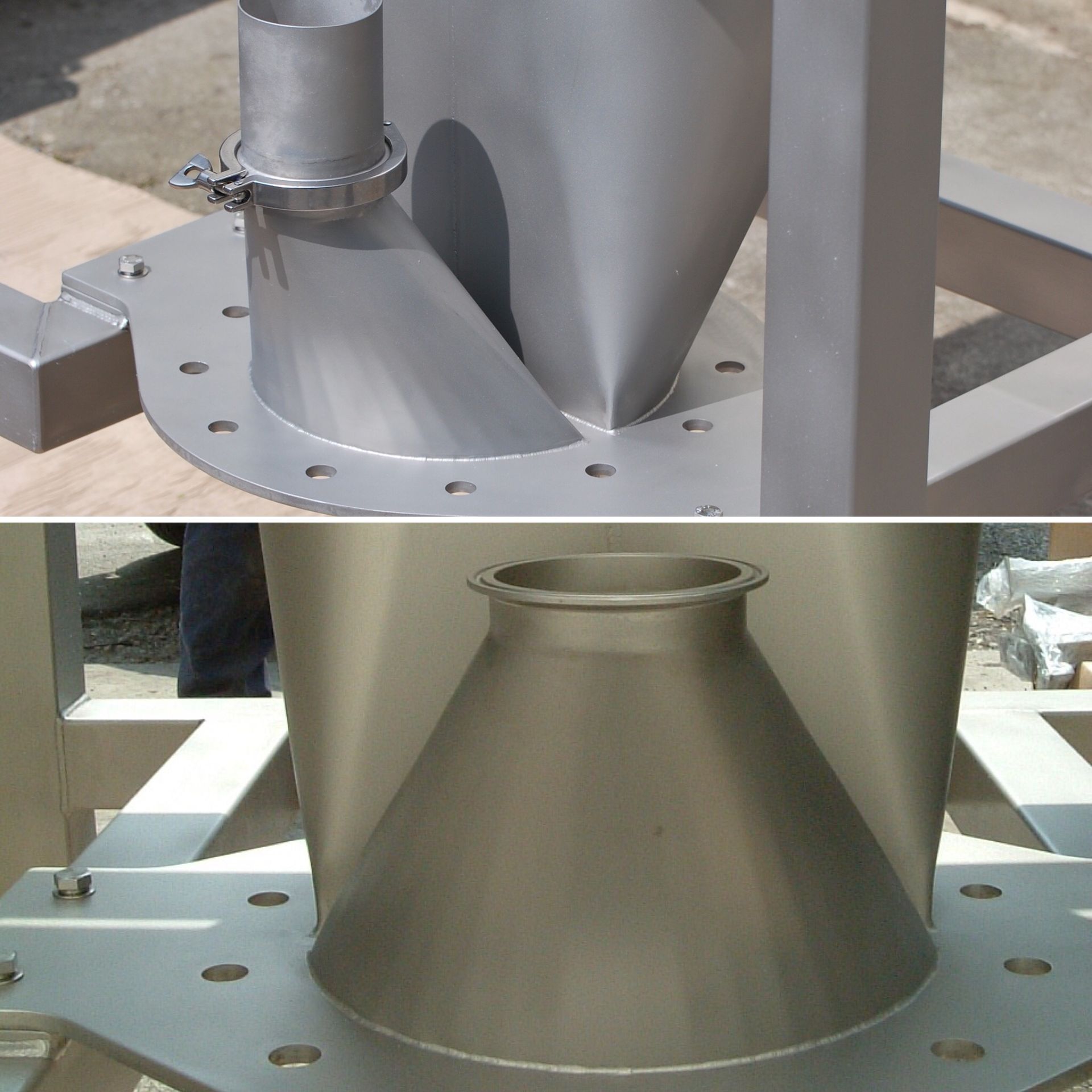

For sheet metal work in particular, these skills were indispensable. Crafting complex components from flat sheets required precise marking, cutting, and shaping—skills that could only be honed through practice and experience. Understanding how to translate a two-dimensional template into a three-dimensional structure was both an art and a science.

These skills fostered an intimate relationship with the materials themselves, enabling engineers to think three-dimensionally while working with two-dimensional templates.

In today’s engineering environment, the same principles come into play, particularly when designing for complex shapes or assemblies. Engineers who possess this foundational knowledge can better anticipate real-world challenges, creating more efficient and accurate designs in 3D modelling software.

Bridging Traditional Craftsmanship with Modern Technology

While 3D CAD and simulation tools provide unparalleled precision and speed, they often rely on assumptions and idealised models. Engineers with a grounding in traditional techniques bring a practical edge to the digital environment. They can:

- Spot potential errors or impractical features in digital models before production.

- Create designs that are easier and more cost-effective to manufacture.

- Leverage insights into material behaviour to inform simulations and improve accuracy.

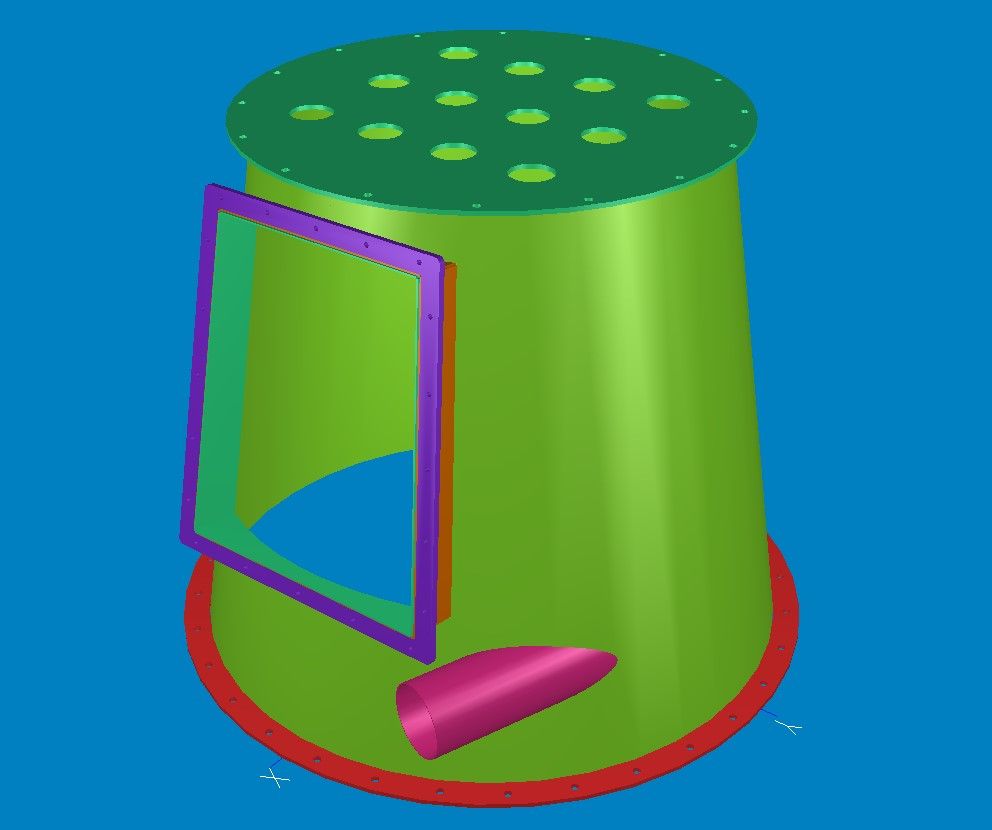

For example, in sheet metal fabrication, understanding the intricacies of bends, folds, and seams ensures that designs not only look good on a screen but also function seamlessly in practice. This synergy between traditional and modern techniques results in better products—ones that are not only visually and dimensionally accurate but also robust, efficient, and optimised for real-world application.

Enhancing Creativity and Problem-Solving

The manual techniques of the past demanded creativity, patience, and ingenuity. When working without the safety net of undo buttons or automated corrections, engineers had to think critically about every step of the process. This mindset continues to benefit modern professionals who understand:

- How to adapt when designs or simulations don’t go as planned.

- How to innovate when faced with complex design challenges.

- How to push the boundaries of what’s possible in fabrication.

Sheet metal work, in particular, exemplifies this creativity. Crafting intricate patterns and precise joints required a problem-solving mindset that extends directly to modern engineering challenges. By merging traditional craftsmanship with today’s cutting-edge tools, modern engineers can approach problems with a unique blend of innovation and practicality.

The Future of Engineering: A Fusion of Old and New

At its core, engineering is about problem-solving and creation. While the tools have evolved dramatically over the decades, the principles remain unchanged. By honouring the traditional skills of marking out and pattern-making—and understanding how they inform modern techniques—we ensure that today’s designs are not only technologically advanced but also grounded in practical, real-world understanding.

Incorporating these timeless insights into the 3D modelling process creates a stronger, more versatile engineering environment. It’s a testament to the idea that the lessons of the past are never obsolete—they’re the stepping stones to the innovations of the future.

Whether you’re designing with cutting-edge software or sketching out ideas on paper, the skills honed by engineers in the 60s, 70s, and 80s remain a powerful asset, enabling the creation of products that are both visionary and grounded in reality.

Contact Us to Benefit from Our Expertise

At Carbro Sheet Metal, we combine decades of hands-on expertise with the latest in modern technology to deliver exceptional engineering solutions. Our deep understanding of traditional marking out and pattern-making, particularly in sheet metal fabrication, allows us to tackle even the most complex projects with precision and efficiency. If you’re looking for innovative designs that are rooted in practical, real-world knowledge, get in touch with us today. Let us show you how the timeless skills of the past can enhance your future projects.